GET A FREE QUOTE!

We will get back to you as soon as possible.

Please try again later.

Our Home Drywall Services

Installs, Repairs, Removal and Renovations

Victoria Drywall stands proud as a beacon of excellence in all drywalling realms. For our residential projects, we specialize in crafting spaces that resonate warmth and comfort, ensuring every living room, bedroom, or basement is impeccably finished to exude a homely charm. This involves precise cuts for electrical outlets, seamless taping and mudding to mask joints, and the delicate art of texture applications for walls and ceilings that are both durable and aesthetically pleasing. We are also available to work in multi-story buildings, such as apartments and condos. Here, our focus sharpens on acoustic and noise-reduction considerations, fire-rated drywall installations, and intricate drywall design implementations that cater to the unique demands of a multi-family building. Efficient scheduling, robust partitioning, and meticulous attention to details like corner beads and recessed lighting cut-outs define our approach. With Victoria Drywall, clients get the assurance of the best drywall experts in Victoria, BC, regardless of the project's scale or nature, backed by a team that understands every nuance of drywalling to perfection.

Residential Drywall

Drywall Installation

Every home is a unique canvas, and at Victoria Drywall, we specialize in ensuring its walls are both sturdy and flawless with our residential drywall installations.

The process begins with a thorough assessment of the space, accounting for its dimensions, architectural intricacies, and the homeowner's specific needs. We then employ precision in measuring and cutting each drywall sheet, ensuring snug fits around windows, doors, and electrical outlets. Our trained team meticulously secures each panel, from corners to center, using high-quality drywall screws and anchors.

Once the drywall is in place, our expertise shines as we seamlessly tape and mud the joints, achieving a smooth surface that's primed and ready for painting or wallpapering.

Home Renovations

Bathroom

Drywall

In areas of your home where moisture is prevalent, such as bathrooms, the right choice of drywall is imperative. At Victoria Drywall, we specialize in bathroom drywall installations that prioritize both aesthetics and functionality. Recognizing the unique challenges posed by bathroom environments, we utilize high-quality moisture-resistant drywall designed to combat the potential damages of humidity and water exposure. This specialized drywall acts as a shield, preventing mold growth and structural compromise. Our team ensures that behind every beautifully finished bathroom wall is a robust defense against moisture, guaranteeing longevity and a healthy space.

Kitchen

Drywall

Transform your kitchen space with Victoria Drywall's specialized drywalling and renovation services. We expertly handle drywall installation, finishing, and custom features, ensuring your kitchen merges functionality with style. From modern backsplashes to seamlessly integrated drywall features, our expertise ensures your kitchen not only looks impeccable but functions flawlessly. We will prioritize using the proper drywalling materials so your kitchen can stand the regular wear and tear of life. Ready for the messiness of a kitchen and easy to clean, our kitchen drywalling services are the best around!

Bedroom

Drywall

We recognize that a bedroom is more than just a space to sleep; it's a personal sanctuary, a place of retreat and rejuvenation. Our bedroom renovation services are tailored to collaborate with clients to craft custom designs that align with their vision and lifestyle needs. From optimizing bedroom layouts to provide greater space and efficiency, to selecting the ideal drywall finishes that ensure a polished look and feel, every detail is carefully addressed. With advanced drywalling tools and materials at our disposal, we guarantee both aesthetic appeal and structural integrity. Don't just update a room; enhance your daily living experience.

New Home Construction

Embarking on new home construction is a significant endeavor, and at Victoria Drywall, we appreciate the importance of laying a flawless foundation for your dream abode.

Our specialized drywall installation services for new home construction seamlessly integrate with the building process. Our experienced team collaborates closely with builders, architects, and homeowners, ensuring that the drywall is perfectly tailored to fit the unique dimensions and design intricacies of your new property. Leveraging state-of-the-art techniques and top-quality materials, we strive to provide walls and ceilings that are not just robust and durable but also exude a polished finesse.

Our drywall contractors' commitment to excellence and precision ensures that every corner, joint, and surface is immaculate, laying the groundwork for the beautiful interiors of your new home.

Trust Victoria Drywall to make your new home's walls the canvas for your future memories.

Drywall

Ceiling Installation

With Victoria Drywall's specialized ceiling drywall services, we elevate the aesthetics of your interiors to new heights. Our team possesses the skills and knowledge to seamlessly install and finish drywall ceilings, ensuring they stand the test of time while providing a smooth and flawless appearance. Whether you're looking to enhance acoustic/noise-reduction properties, integrate recessed lighting, or simply refresh a dated ceiling, our drywall craftsmen approach each project with care and precision.

By choosing Victoria Drywall, you're not only investing in the visual appeal of your space but also in the structural integrity and quality of work that only our expert drywallers can deliver. Elevate your interiors with a ceiling that truly complements and elevates your home's design.

Garage & Shop Renovations

Transform your garage into a polished and functional space with Victoria Drywall's specialized garage drywall services. Often overlooked, a well-drywalled garage can elevate the entire aesthetic of your home, providing a clean and insulated environment for vehicles, tools, and hobbies alike. Whether you're aiming to create a workshop, a fitness zone, or simply want to enhance the structural integrity and appearance of your garage, our team brings the same dedication and precision to these drywall projects as we do to interior living spaces.

Utilizing moisture-resistant and durable drywall materials suitable for varying garage conditions, Victoria Drywall ensures your space is not only visually appealing but also resilient to the unique demands of a garage environment. Let us redefine your garage experience with exceptional craftsmanship tailored to your drywalling needs, choose us as your local drywalling company!

Guest Houses & Vacation Homes

These special abodes serve as tranquil retreats or welcoming spaces for visitors, and their walls should echo the warmth and relaxation they promise. With our specialized drywall installation services tailored for vacation properties, we ensure that every room exudes comfort and aesthetic appeal.

Whether it's a picturesque lakeside cabin or a cozy guest house nestled in your backyard, our seasoned team of drywalling pros approach each project with keen attention to detail, aligning with the distinctive ambiance these spaces command. Using premium materials combined with cutting-edge installation techniques, we deliver interiors ready to enhance the restful vibes of your getaway spaces.

For drywall and interiors that complement the serene essence of your vacation homes, rely on Victoria Drywall's unmatched expertise!

Homes are living narratives, and over time, they can display signs of wear, be it from shifting foundations, accidental impacts, or natural aging. At Victoria Drywall, we understand the nuances and intricacies of residential drywall repair.

Whether it's a minor crack, a water damage spot, or a larger hole, our team employs meticulous techniques to restore the wall or ceiling to its original glory. Utilizing top-tier drywall compound, expertly matched textures, and precision tools, we ensure that the repaired area seamlessly blends with the surrounding surface.

Our process begins with a thorough assessment of the damage, followed by a careful preparation of the area. We then apply layers of compound, drywall tape, and other materials as needed, finishing with sanding and texture application to achieve a flawless finish. With Victoria Drywall, homeowners can rest assured that their spaces will be rejuvenated with care, expertise, and an unwavering commitment to quality by our drywalling contractors.

Drywall Repair Services

Hole Repair

We understand that accidents happen, leading to unsightly holes in your walls. Our dedicated drywall repair service swiftly addresses these imperfections, restoring your wall to its original pristine condition. With a team of seasoned professionals, we employ advanced repair techniques and superior materials, ensuring the mended area blends seamlessly with the rest of your wall.

Ceiling Repair

There are unique challenges posed by damaged residential ceilings, and this is something we understand. Whether it's due to water leaks, age, or other factors, our adept team is skilled at addressing all ceiling drywall issues with precision. Using quality materials and specialized techniques, we restore your ceiling's aesthetics and integrity, ensuring a smooth, flawless finish. Give us a call and take confidence in knowing your ceiling will be repaired to the highest standards of craftsmanship and durability.

Crack Repair

Over time walls can develop cracks due to various reasons, from natural settling to humidity changes. Our specialized drywall crack repair service is tailored to address these blemishes, rejuvenating your wall to its initial impeccable state. Our skilled craftsmen utilize tried-and-true crack repair methods combined with premium materials, ensuring that the remedied crack is indistinguishable from the surrounding wall.

Water Damage Repair

Water damage can severely compromise the integrity and appearance of your drywall. At Victoria Drywall, we specialize in addressing and rectifying water-damaged drywall areas with precision. With the utilization of premium-grade materials for the repair, we remove affected portions, safeguard against mold, and restore your wall or ceiling to its original state.

Move-In & Move-Out Repair

Moving in or out of a home can sometimes lead to unexpected scuffs, dings, or holes in your drywall. Victoria Drywall offers specialized move-in and move-out repair services to bring those walls back to their pristine condition. Whether it's minor touch-ups or more extensive repairs, our experienced team ensures a seamless finish, making your space look as good as new. We will handle the intricacies of move-related repairs, helping you start fresh or leave your previous home in impeccable shape.

Smoke Damage Repair

Smoke damage can leave lasting marks and odors on your drywall, affecting both the aesthetics and air quality of your space. At Victoria Drywall, we're adept at addressing smoke-damaged surfaces with precision, leading to the best drywall repair services in Victoria. Using advanced techniques and high-quality materials, we eliminate discolorations and seal in odors, rejuvenating your walls and ceilings. You can rely on us to restore the pristine appearance of your interiors while ensuring a healthier living environment.

Drywall

Mudding, Taping and Sanding

Mudding

At Victoria Drywall, the mudding process is approached with an artisan's precision. It starts with the application of joint compound, or 'mud', to seamlessly merge individual drywall sheets. This compound fills in gaps, covers fasteners, and ensures an even, cohesive surface across the entire wall or ceiling. We methodically layer the mud, allowing each application to dry thoroughly before the subsequent layer, guaranteeing a sturdy, crack-resistant foundation.

Taping

Once the mudding process sets the groundwork, our experts employ taping to fortify and refine these joints. Taping involves applying a specialized drywall tape over the fresh mud, which helps prevent future cracking and reinforces the bond between sheets. At Victoria Drywall, we choose tapes that complement the specific needs of the project, ensuring that no seam is left visible, and every joint is strengthened for enduring resilience.

Sanding

The final touch in our trifecta of excellence is drywall sanding. This process is crucial to achieving a silky smooth finish, ready for paint or wallpaper. At Victoria Drywall, our professionals use specialized sanding tools to methodically buff away any tiny imperfections or ridges left by the taping knife. This meticulous attention to detail ensures a uniformly smooth surface, free of blemishes. The result is a wall or ceiling that's not just robust and functional but also a canvas of impeccable beauty, ready to complement your home's aesthetics.

Drywall Finishing

Victoria Drywall takes pride in offering top-tier residential drywall finishing services, setting the gold standard for impeccable walls and ceilings.

Our seasoned drywall craftsmen understand that the finishing touch can transform a room, which is why we provide a myriad of drywall finishing options tailored to your aesthetic and functional needs. From the smoothest skim coats for a polished modern look to distinctive textures that add character and depth, our range of drywall finishes cater to diverse tastes and styles. But it's not just about aesthetics; our finishes are applied with precision and durability in mind, ensuring they stand up to the test of time and daily life.

With Victoria Drywall at the helm, every surface becomes a canvas, and every finish a work of art.

The Levels of Drywall Finishing

At Victoria Drywall, we pride ourselves on offering an extensive range of drywall finishing, catering to the diverse needs and preferences of our customers. There are six distinct levels of drywall finishing ensure that each project aligns perfectly with its intended aesthetic and function, ranging from 0-5:

At level 0, drywall is simply hung and fastened, and no finishing of any type has been done. Level 0 is considered "pre-finishing" in the industry, as it is nothing but raw Sheetrock hung and fastened.

Best suited for areas that aren’t regularly visible, such as attics or service corridors, this level involves merely taping joints without further finishing. It's a foundational finish, prioritizing function over aesthetics.

This level sees the addition of a coat of joint compound over embedded tape at the drywall joints. It’s typically chosen for garages or other spaces where appearance isn’t a primary concern, but some level of seam treatment is desired.

Moving towards a more polished appearance, Level 3 involves applying a thin layer of joint compound over the tape and screws. This is often selected for walls that will receive a heavy texture, like a knockdown finish, which can mask minor imperfections.

Ideal for most residential walls and ceilings, this level includes a full tape coat and two additional coats of joint compound, ensuring a smooth and seamless appearance. It's perfect for walls that will be painted or where light textures will be applied.

The epitome of drywall finishing, Level 5 provides the smoothest possible wall surface. After following the processes of Level 4, we apply a thin skim coat of joint compound over the entire wall or ceiling. This level is recommended for areas with a lot of natural or artificial light, ensuring no shadowing or imperfections are visible, rendering walls and ceilings with a pristine, gallery-like finish.

The Types of Drywall Finishing

Often considered the pinnacle of drywall finishes, our smooth finish offers a sleek and flawless surface, ideal for modern and minimalist interiors. Our team meticulously applies multiple coats, ensuring the wall is perfectly flat and free from imperfections.

A popular choice for adding depth and character, the knockdown texture involves applying splatters of drywall compound that are later smoothed down, creating a mottled texture on the wall. It's perfect for hiding minor imperfections and bringing a warm, artisanal touch to a room.

As the name suggests, this finish mimics the texture of an orange's skin. It's a subtle texture, achieved by spraying a mix of drywall compound and water onto the wall. The result is a surface with tiny raised bubbles, adding a tactile dimension without being overly bold.

Hand-applied using a trowel, this finish creates a pattern of thin lines, swirls, and arcs. Each skip trowel application is unique, allowing for a bespoke touch to your walls, making them stand out in their individuality.

Often used for ceilings, the popcorn texture is known for its bumpy appearance, reminiscent of cottage cheese. While it's a classic choice for masking ceiling imperfections and providing sound dampening, it's also a style statement in its own right.

Elegant and timeless, the sand swirl involves adding sand to the joint compound and creating swirl patterns using a brush. The result is a wall that is not only visually enticing but also rich to the touch.

Moving away from traditional sharp-edged corners, bullnose corners provide a rounded, smooth transition between walls. They not only add an aesthetic appeal but are also safer, reducing the chance of injury from sharp edges.

Drywall

Priming and Painting

Our priming and painting services are emblematic of our commitment to excellence in every project. Priming is a vital step we prioritize, as it ensures that the drywall surface is sealed, allowing for optimal paint adhesion and a uniform appearance. With our use of top-of-the-line primers, we guarantee a surface ready to receive its final hue. Following priming, our adept painting team takes center stage, employing only the finest quality paints that promise both vibrant color and enduring resilience for your home.

Our drywalling experts are well-versed in the latest painting techniques and trends, ensuring a flawless application tailored to your design aspirations.

With Victoria Drywall's priming and painting services, you're not just getting a color change; you're investing in a transformation rooted in expertise and quality.

Drywall

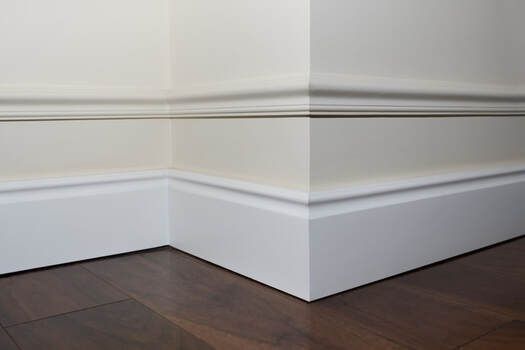

Trim & Baseboards

Trim and baseboards really put the final touches on completing a rooms look, and that's why we take them seriously! These elements, while seemingly subtle, can transform the ambiance of a room, offering both functional benefits and elevated aesthetics. Not only do they provide your drywall and home protection against daily wear, but they also serve as an accent that frames a space beautifully.

Our Victoria drywall contractors are equipped to offer a myriad of baseboard and trim design choices, aligning with both modern and traditional interiors. Using advanced baseboard installation techniques and top-tier trim materials, we ensure every trim and baseboard complements the room's design perfectly. With Victoria Drywall by your side, your interiors will radiate elegance and precision in every corner.

The Types of Drywall Trim

With its signature rounded edge, bullnose trim offers a smooth transition between drywall surfaces, giving a modern touch to room corners and window returns. At Victoria Drywall, our meticulous installation ensures these gentle curves maintain their sleek appearance, accentuated by precise mudding and sanding for that polished look.

L trim, often called angle bead, provides a sharp and straight edge perfect for framing the likes of windowsills and door frames. Our team at Victoria Drywall places emphasis on precision, ensuring that every corner is sharp and every edge emphasizes the room's structural definition.

Designed for edges of drywall that don't meet another surface, J trim ensures a clean finish without the necessity of a full frame. Victoria Drywall's specialists are adept at handling these trims, guaranteeing a refined touch to any unenclosed edge.

Often referred to as "Deep Leg" trim, the U trim lends a pronounced, decorative edge around fixtures such as doors and windows. Our approach seamlessly integrates U trims to complement the fixtures, bringing both functionality and a hint of sophistication.

Tailored for larger rooms or spaces subject to temperature fluctuations, the expansion bead trim flexibly accommodates structural shifts, preventing drywall cracks. Victoria Drywall takes a strategic approach, placing these trims in areas most prone to movement, safeguarding the wall's integrity and appearance.

Specifically designed to offer protection to drywall edges, the flat tear-away trim comes equipped with a strip ensuring a seamless edge transition to adjacent materials. Trust in Victoria Drywall's expertise to maximize the benefits of the tear-away strip, leaving a clean, integrated finish every time.

Custom Drywall Projects

Built-In Drywall Shelving

Victoria Drywall is able to help you elevate the aesthetics and functionality of your living spaces with bespoke built-in drywall shelving solutions. Expertly integrating into your walls, our custom shelving not only offers a streamlined and modern appearance but also maximizes room utility without consuming floor space. Whether you envision a minimalist design for your living room, a chic bookcase in your study, or a multi-functional nook in your bedroom, our team collaborates closely with you to craft and install a drywall shelving system tailored to your exact requirements. By combining artistic design with impeccable craftsmanship, Victoria Drywall transforms ordinary spaces into sophisticated, organized havens.

Installing lighting within Drywall and Ceilings

Illuminate your living spaces in the most elegant and innovative manner with Victoria Drywall's integrated lighting solutions. Seamlessly embedding lights directly into drywall or ceilings, we craft lighting designs that radiate sophistication and enhance ambiance. Beyond traditional lighting fixtures, our built-in approach offers a clean and uncluttered aesthetic, optimizing room spaces while creating captivating focal points. From subtle accent lights in drywalls to expansive luminous ceilings, our team pairs technical drywall expertise with artistic vision to deliver lighting that's not just functional but also a transformative design element. Trust Victoria Drywall to blend illumination and architecture harmoniously, turning every space into a masterpiece of light and texture.

Acoustical Suspended Ceilings

Our acoustical suspended ceilings are a cornerstone of our custom residential drywalling services. These specialty ceilings are more than just visually appealing; they are engineered to provide outstanding sound absorption, enhancing the acoustic comfort of any space. Whether you're looking to achieve a serene environment free from outdoor noises or wish to enhance the acoustic properties of a home theater, our drywalling experts design and install these suspended systems to meet your specific needs. Blending aesthetics with function, our acoustical suspended ceilings are tailored to seamlessly integrate into your home's design, adding both value and tranquility. Trust in Victoria Drywall to elevate your living experience with the fusion of artistry and acoustic innovation.

Drywall Removal

At Victoria Drywall, we prioritize a diligent approach to drywall removal, essential for various home renovation projects. Whether addressing damages, mitigating issues like mold or asbestos, or adapting to a fresh layout, our skilled team ensures the utmost precision and care throughout the process.

We begin this drywall service by safeguarding your belongings, covering or relocating items to shield them from dust and debris. For optimal safety, we disconnect the electricity in the work area, particularly when wall outlets or switches are involved. Our professionals initiate the removal from the top corner of the wall, making a careful incision and then methodically detaching the drywall, preventing abrupt breaks that can create messes or hazards. As sheets are taken down, we efficiently segment them for hassle-free disposal. Equipped with protective gear, our team guarantees a safe and tidy removal process. In homes built before the 1980s, where asbestos might be a concern, trust in our specialized removal methods to ensure complete safety.

Once the old drywall is clear, Victoria Drywall contractors' conducts a thorough evaluation of wall studs, insulation, and wiring, prepping the area for the next phase of your renovation journey.

Removing Damaged Drywall

We understand that sometimes the best solution is a fresh start. When your drywall is damaged beyond simple repairs, our drywall removal service ensures safe and efficient extraction of the compromised sections. Our trained professionals handle each project with utmost care, minimizing disruption and ensuring the area is prepared for a flawless new installation.

With Victoria Drywall by your side, damaged walls are swiftly transformed, setting the stage for a renewed and revitalized space.

Popcorn Ceiling Removal

Popcorn ceilings, once a popular choice for homes due to their acoustic properties and ability to hide imperfections, have fallen out of favor in contemporary design. Many homeowners now seek their removal for a cleaner, modern aesthetic or concerns about asbestos content in older installations.

At Victoria Drywall, our expertise in popcorn ceiling removal ensures a smooth transition to a more refined ceiling finish. The process begins with a comprehensive assessment to determine if asbestos is present—common in ceilings installed before the 1980s. If detected, we deploy specialized techniques to ensure safe removal. For ceilings without asbestos, our team employs a meticulous procedure to moisten and scrape away the texture, capturing the bulk of the debris with minimal mess.

Safety precautions are paramount; we protect all surfaces and furnishings with plastic sheeting, ensuring a contained work area. Once the popcorn material is removed, the ceiling is inspected for any imperfections. These are seamlessly patched, sanded, and prepped, setting the stage for a fresh, updated finish of your choice. You can trust Victoria Drywall to transform your dated popcorn ceiling into a smooth, contemporary canvas that enhances your living space.

Drywall Ceiling Replacements

After the removal of a popcorn ceiling, achieving a smooth, pristine finish is crucial for a modern look and feel. At Victoria Drywall, we specialize in ceiling replacements post-popcorn removal. Using premium materials and precision techniques, we install a new, sleek ceiling surface that not only elevates the look of your space but also meets the highest standards of durability and quality.

We understand the nuances of ceiling replacements and ensure a seamless transition from the old to the new.

Health & Safety

Popcorn ceiling removal is not just about aesthetics; it's also a matter of health and safety. At Victoria Drywall, we prioritize your well-being during the removal process. Popcorn ceilings, particularly those installed before the 1980s, can contain asbestos—a hazardous material when disturbed.

Our drywall installers and drywall contractors are equipped with the necessary protective gear and employs specialized techniques to safely and effectively remove these textured ceilings. We take precautions to minimize dust and airborne particles, ensuring your living space remains clean and free from potential hazards.

Our Service Areas

-

Southern Vancouver Island

Victoria Drywall is based within Victoria but we will travel to:

- Oak Bay

- Saanich

- Esquimalt

- View Royal

- Marigold

- Cadboro Bay

- Arbutus

- Gordon Head

- Cordova Bay

- Langford

- Colwood

- Brentwood Bay Millstream

- Goldstream

-

Victoria West

Craigflower, Wilson, Russell, Catherine, Kimta, Tyee

-

Burnside Gorge

Gorge Rd East, Harriet, Washington, Jutland, Burniside Rd, Alpha, Tolmie, Douglass, Topaz, Government

-

Hillside Quadra

Finlayson, Summit, Blackwood, Cook, Quadra, Hillside, Kings

-

Oaklands

Cedar Hill, Cook, Cedar Hill, Hillside, Gosworth, Doncaster, Shelbourne, Kings, Haultain, Ryan

-

North Park

Caledonia, Pandora

-

Fernwood

Yates, Begbie, Gladstone, Belmont, Chambers

-

Jubilee

Oak Bay, Fort, Richmond, Leighton

-

Downtown

Wharf, Chatham, Douglas, Johnson, Quadra, Blanshard, Fort

-

Rockland

Joan Crescent, Rockland, Richmond, Despard, Richardson

-

Gonzales

Ross, Holly Wood Cr, Fairfield, Foul Bay

-

Fairfield

Cook, Rockland, May, Faithful, Linden, Moss, Failfield, Kipling, Arnold, St. Charles

-

James Bay

Erie, Montreal, Belleville, Superior, Simcoe, Oswego, Dallas Rd, Menzies, Toronto, Douglas, Government